Sponge is a porous material with good water absorption and can be used for cleaning items.

Commonly used sponges are made of wood cellulose fibers or foamed plastic polymers. There are also natural sponges made from sponge animals, most of which are used for body cleaning or painting. In addition, there are three types of synthetic sponges made of other materials: low-density polyether (non-absorbent sponge), polyvinyl alcohol (high-absorbent material, no obvious pores) and polyester.

Production Process

1. Mix foaming resin, foaming assistant and binder resin (to make the finished product have adhesiveness);

2. Perform foam processing. 80 parts of ethylene vinyl acetate (EVA), 20 parts of APAO PT 3385, 20 parts of azodicarboxamide, 19 parts of CaCO, and 0.6 parts of dicumyl peroxide are mixed together and put in a mold to foam, When the closed hole is broken by mechanical force, a foamed sponge can be obtained. Its density (d) is 0.028 g / cm and its compression hardness at 25% is 1.9 KPa.

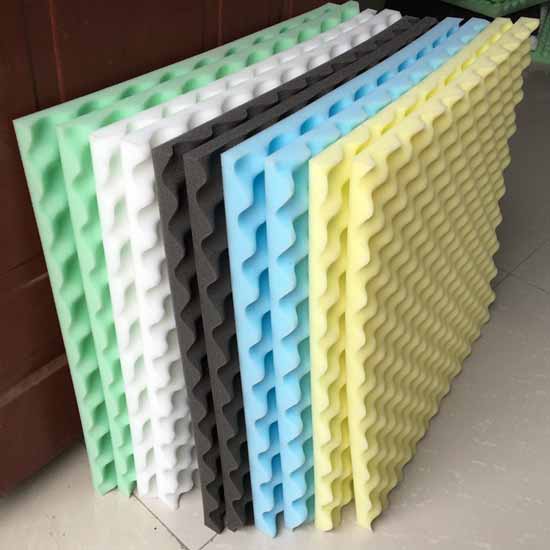

PU sponge mainly includes polyester and polyether type which can be sliced or rolled, and can also be compound processed, hot-pressed and blasted according to customer requirements. Because of its characteristics of heat preservation, heat insulation, sound absorption, shock absorption, flame retardant, antistatic, and good ventilation, PU sponges are involved in various industries, including automobile industry, battery industry, cosmetics industry, bust underwear manufacturing and high-end furniture Manufacturing, etc.

Sponge type

1) Chemical sponge, Polyurethane soft foam rubber. Polyurethane is one of the most common polymer materials in life. It is widely used to make various "sponge" products. As well as elastic materials for shock and anti-friction applications, such as shoe soles, tractor tank track substrates.

2) Industrial sponge, There are many types of sponges used in industrial production, including foam sponges, styling sponges, rubber sponges, memory sponges, etc.

a. styling sponges, This material is made of polyurethane, mixed with various additives such as foaming agent, and pressed into a simple mold to warm up to produce different shapes of sponge. It is suitable for swivel sofa cushions, back cotton, and also has a small amount of armrests. Made of cotton. Using 55 # ~ 60 # material density, its flexibility is more in line with relevant national standards. The elastic hardness of the sponge can be adjusted according to the different parts of the product. Generally, seat cotton is higher in hardness and density, back cotton is second, and pillow cotton is softer.

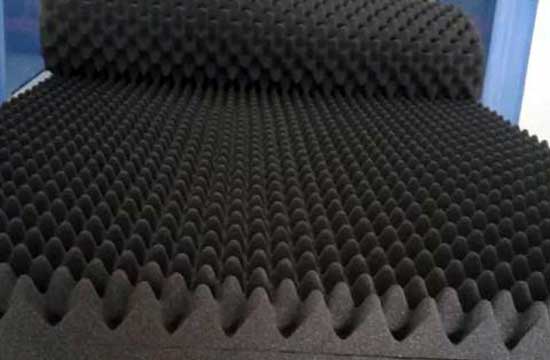

b. foam sponges, This material is foamed with polyether, like foamed bread. It can be foamed with mechanical equipment or artificially surrounded by wooden boards. The foamed cotton is like a square loaf. The slicer is used to go through the slicing process to cut the thickness according to different requirements. The foam can also be adjusted for softness . Seat cotton generally uses 25 ~ 28kg / m3, others use 20 ~ 22kg / m3 density. Although the hardness and density of sponge are directly related, they are also related to different additive formulas. Therefore, the industry is divided into high elasticity, gray super, black gray super, and soft cotton. When designing and using the product, it should be reasonably and scientifically matched according to different shapes and structures. Generally, it is divided into three parts of upper, middle and lower parts with different elasticity and density of sponge. There is a kind of fire-resistant cotton material (flame-retardant cotton) in the sponge. In fact, before the foaming of the sponge, a fire retardant is added to the material formula, such as chlorine and bromine. When the sponge catches fire, it can generate fire extinguishing smoke and block the smoke.

Commonly used sponges are made of wood cellulose fibers or foamed plastic polymers. There are also natural sponges made from sponge animals, most of which are used for body cleaning or painting. In addition, there are three types of synthetic sponges made of other materials: low-density polyether (non-absorbent sponge), polyvinyl alcohol (high-absorbent material, no obvious pores) and polyester.

Production Process

1. Mix foaming resin, foaming assistant and binder resin (to make the finished product have adhesiveness);

2. Perform foam processing. 80 parts of ethylene vinyl acetate (EVA), 20 parts of APAO PT 3385, 20 parts of azodicarboxamide, 19 parts of CaCO, and 0.6 parts of dicumyl peroxide are mixed together and put in a mold to foam, When the closed hole is broken by mechanical force, a foamed sponge can be obtained. Its density (d) is 0.028 g / cm and its compression hardness at 25% is 1.9 KPa.

PU sponge mainly includes polyester and polyether type which can be sliced or rolled, and can also be compound processed, hot-pressed and blasted according to customer requirements. Because of its characteristics of heat preservation, heat insulation, sound absorption, shock absorption, flame retardant, antistatic, and good ventilation, PU sponges are involved in various industries, including automobile industry, battery industry, cosmetics industry, bust underwear manufacturing and high-end furniture Manufacturing, etc.

Sponge type

1) Chemical sponge, Polyurethane soft foam rubber. Polyurethane is one of the most common polymer materials in life. It is widely used to make various "sponge" products. As well as elastic materials for shock and anti-friction applications, such as shoe soles, tractor tank track substrates.

2) Industrial sponge, There are many types of sponges used in industrial production, including foam sponges, styling sponges, rubber sponges, memory sponges, etc.

a. styling sponges, This material is made of polyurethane, mixed with various additives such as foaming agent, and pressed into a simple mold to warm up to produce different shapes of sponge. It is suitable for swivel sofa cushions, back cotton, and also has a small amount of armrests. Made of cotton. Using 55 # ~ 60 # material density, its flexibility is more in line with relevant national standards. The elastic hardness of the sponge can be adjusted according to the different parts of the product. Generally, seat cotton is higher in hardness and density, back cotton is second, and pillow cotton is softer.

b. foam sponges, This material is foamed with polyether, like foamed bread. It can be foamed with mechanical equipment or artificially surrounded by wooden boards. The foamed cotton is like a square loaf. The slicer is used to go through the slicing process to cut the thickness according to different requirements. The foam can also be adjusted for softness . Seat cotton generally uses 25 ~ 28kg / m3, others use 20 ~ 22kg / m3 density. Although the hardness and density of sponge are directly related, they are also related to different additive formulas. Therefore, the industry is divided into high elasticity, gray super, black gray super, and soft cotton. When designing and using the product, it should be reasonably and scientifically matched according to different shapes and structures. Generally, it is divided into three parts of upper, middle and lower parts with different elasticity and density of sponge. There is a kind of fire-resistant cotton material (flame-retardant cotton) in the sponge. In fact, before the foaming of the sponge, a fire retardant is added to the material formula, such as chlorine and bromine. When the sponge catches fire, it can generate fire extinguishing smoke and block the smoke.

c. rubber sponges, One kind of sponge. It is made of natural latex foamed main material. It has rubber characteristics, excellent elasticity, good resilience, and does not deform, but it is expensive, 3 ~ 4 higher than foamed sponges.

d. recycled sponge, Recycled sponge, the internationally-known English name BONDED FOAM, is a new type of product and a sponge treatment method commonly used worldwide. Recycled sponge belongs to the recycling of industrial waste of polyurethane products. Its use value is no less than that of sponge. It is made of industrial sponge scraps by crushing, stirring glue, steam, high-temperature sterilization, sterilization, deodorization and compression molding. The production cost is greatly reduced from the use of production costs. It has good elasticity, good resistance, no deformation and no odor. It can be made into various densities according to customer needs. Above, it has the characteristics of high efficiency flame retardant, good tensile force, large elasticity, no deformation, etc., and then sterilized by high-pressure steam, which is environmentally friendly, economical and practical. Can be widely used to make sofas, mattresses, boss chairs, sports equipment, such as sponge gymnastic mats, sponge fitness mats, sponge wrestling mats, sponge car cushions and other products, this product has been widely accepted by countries around the world.

The broken sponge in the recycled sponge is the unused industrial small pieces and broken particles left after industrial cutting. This broken sponge is a product that has passed the quality inspection and passed the standard. At the same time, this small piece of particles is easier to shape and shape. Features are more durable.

In the recycled sponge processing system, it is absolutely not allowed to use the recycled sponge in the processing of recycled sponge, and the used sponge taste is very obvious. A significant part of the taste of recycled sponges on the market is due to the processing of used sponges. Therefore, a good consumer of recycled sponges can rest assured to buy and use. In various fields of national economic construction and people's life, the annual production of polyurethane products in the world is close to 7 million tons. Such products will have a large amount of waste during production and after consumption: due to different production methods, generally Produces 8% -15% of corner waste. In addition, after the polyurethane products exceed the useful life, their performance will be greatly reduced and scrapped. All these wastes must be effectively recycled and reused.

For sponge, it's also widely used to make protector foam inlay for cosmetics, glass bottles, products shipping, etc. In Unico, that's possible to make custom design foam inlay with your every single request.

For sponge, it's also widely used to make protector foam inlay for cosmetics, glass bottles, products shipping, etc. In Unico, that's possible to make custom design foam inlay with your every single request.